Spotlight Video

Features

- Controlled with an American made PLC / HMI combo

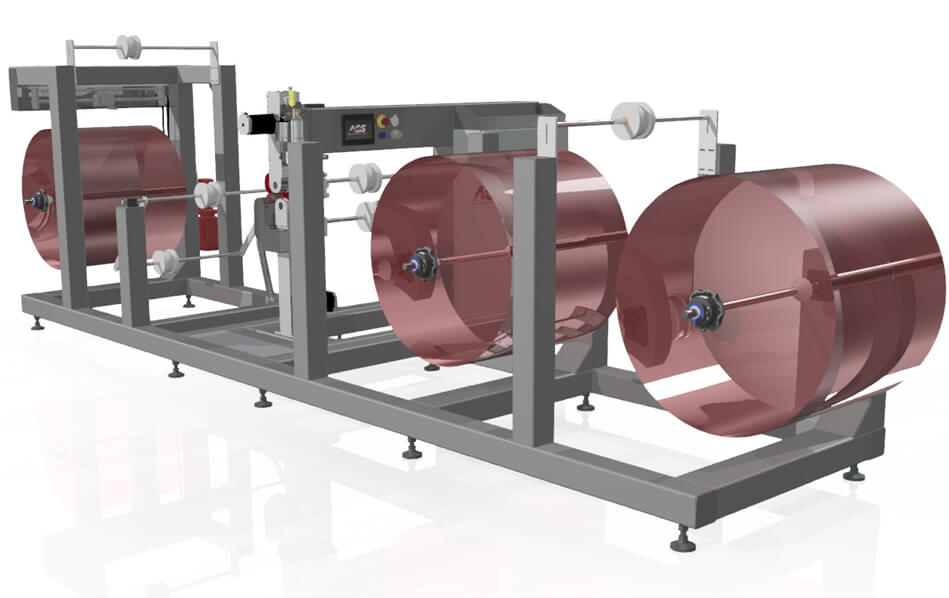

- Built on 1 frame, ready to plug and play

- Twin unwind stands with mechanical brake

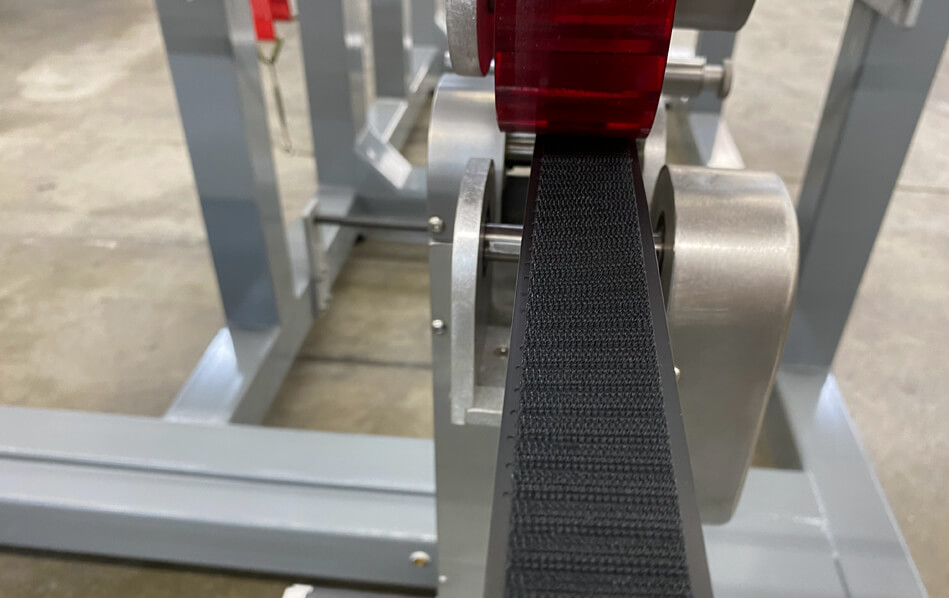

- Overbuilt guiding with micro-adjustments

- Oscillating rewind to produce square finished rolls

- Can be custom built to your application

Requirements & Capabilities

- Power Requirements: 208-230 Volts - Single Phase or Three Phase

- Air Requirements: 80 psi, 4 CFM air pressure required

- Electric Codes: NFPA 70, 79 NEC Guidelines

- Max Temp Hot Air: 1382° F (750° C)

- Max Temp Hot Wedge: 932° F (500° C)

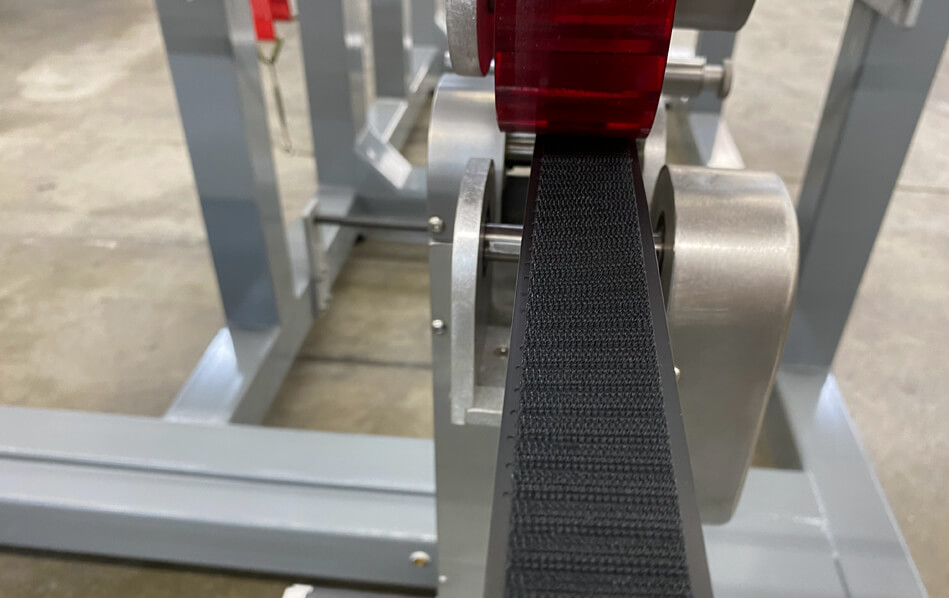

- Seam Width: 1/2" to 2" (12.7mm to 50.8mm)

- Welding Cycle: Up to 110ft/min (33.5 m/min)

Size & Specs

- Throat Width: 36" standard (92cm)

- Width: 24" (61cm)

- Length: 70" (178cm)

- Height: 51" (129cm)

Weldable Materials

- Vinyl (PVC) laminated fabrics

- Vinyl-coated fabrics

- Vinyl films

- Polyurethane films

- Polyethylene (PE)

- Non-woven polyester

- Polypropylene-coated fabrics

- Woven polypropylene

- Non-woven polypropylene

- Thermoplastic rubber fabrics

- Acrylics for awning and marine covers

- Fusing tape

- Weldable webbings

- Any thermoplastic material / fabric

If your material and/or fabric is not listed, please contact ACS Inc. for a product test.

Request a Quote from Our Sales Team

Call Now: +1-330-639-4878